Incoloy Alloy

925

Incoloy 925 Introduction

Precipitation

Strengthened Alloy

Resistance

Behavior

Overview

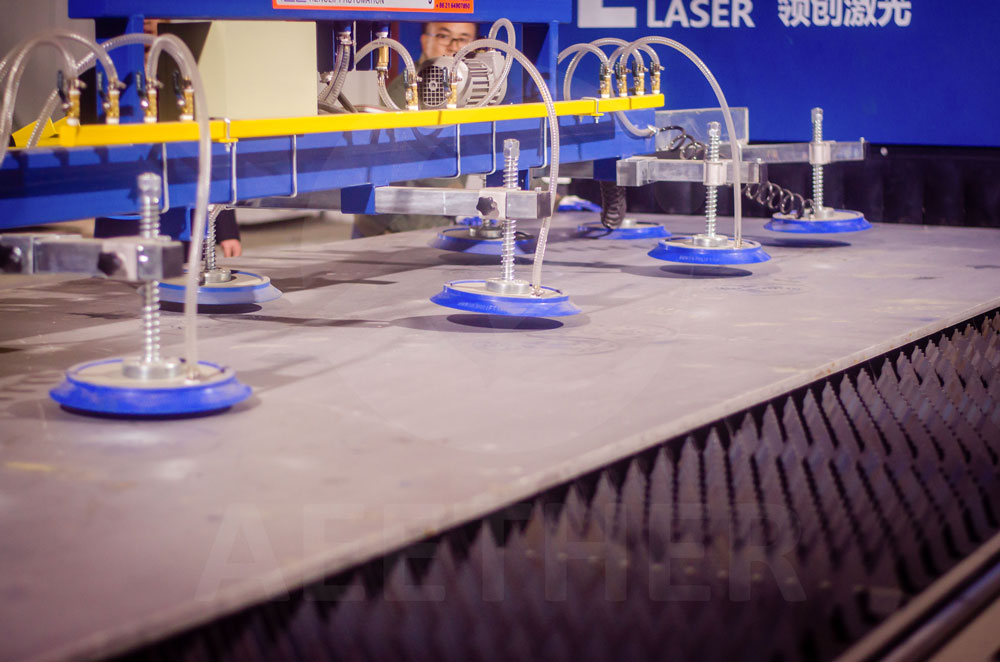

As a leading supplier & manufacturer in China, AEETHER supply cost-effective Incoloy 925 Products.

INCOLOY® alloy 925 (UNS N09925) is an agehardenable nickel-iron-chromium alloy with additions of molybdenum, copper, titanium and aluminum. The alloy’s chemical composition is designed to provide a combination of high strength and excellent corrosion resistance. The nickel content is sufficient for protection against chloride-ion stresscorrosion cracking. The nickel, in conjunction with the molybdenum and copper, also gives outstanding resistance to reducing chemicals. The molybdenum aids resistance to pitting and crevice corrosion. The alloy’s chromium content provides resistance to oxidizing environments. The titanium and aluminum additions cause a strengthening reaction during heat treatment.

INCOLOY alloy 925 is used in various applications requiring a combination of high strength and corrosion resistance. Because of the alloy’s resistance to sulfide stress cracking and stress-corrosion cracking in “sour” (H2S containing) crude oil and natural gas, it is used for down-hole and surface gaswell components including tubular products, valves, hangers, landing nipples, tool joints and packers. The alloy is also useful for fasteners, marine and pump shafting and high-strength piping systems.

Corrosion Resistance

INCOLOY alloy 925 has a high level of corrosion resistance. In both reducing and oxidizing environments, the alloy resists general corrosion, pitting, crevice corrosion, intergranular corrosion and stress-corrosion cracking. Some environments in which INCOLOY alloy 925 is particularly useful are “sour” (H2S containing) crude oil and natural gas, sulfuric acid, phosphoric acid, and seawater.

The tests involve exposure of stressed C-ring specimens (made from a portion of tubing cross section) to a solution containing hydrogen sulfide, sodium chloride and acetic acid.

Incoloy 925 Chemical Composition

Try our Premium Products

Incoloy 925 Standards

Data Sheet

Physical Properties

| Density | g/cm3 | 8.08 | |

|---|---|---|---|

| lb/in.3 | 0.292 | ||

| Melting Range | °F | 2392 - 2490 | |

| °C | 1311 - 1366 | ||

| Electrical Resistivity | ohm-circ mil/ft | 701 | |

| μΩ-m | 1.17 | ||

| Permeability at 200 oersted (15.9 kA/m) | 1.001 | ||

Mechanical Properties

| Form/Condition | Tensile Strength | Yield Strength (0.2% Offset) |

Elongation | Hardness | ||

|---|---|---|---|---|---|---|

| ksi | MPa | ksi | MPa | % | Rockwell | |

| Round/Solution-Annealed | 99.3 | 685 | 39.3 | 271 | 56 | 76 B |

| Round/Solution-Annealed and Aged | 167.3 | 1154 | 120.6 | 832 | 27 | 32 C |

| Cold Drawn Tubing/Solution-Annealed and Aged | 172.5 | 1189 | 120.4 | 830 | 27 | 35 C |

Incoloy 925 Applications

Related Article

More Incoloy Grades +

800

Si

C

Mn

Al

Ti

Cu

Fe

Cr

Ni

800H

Si

C

Mn

Al

Ti

Cu

Fe

Cr

Ni

800HT

Si

C

Mn

Al

Ti

Cu

Fe

Cr

Ni

803

Si

C

Mn

Al

Ti

Cu

Fe

Cr

Ni

825

Si

Mn

Al

Ti

Cu

Mo

Fe

Cr

Ni

832

Si

Ti

Cu

Fe

Cr

Ni

864

Si

C

Mn

Ti

Cu

Mo

Fe

Cr

Ni

890

Si

C

Mn

Ti

Cu

Nb

Mo

Fe

Cr

Ni

903

Al

Ti

Co

Nb

Fe

Ni

907

Si

Al

Ti

Co

Nb

Fe

Ni

908

Si

Mn

Al

Ti

Cu

Co

Nb

Fe

Cr

Ni

909

Si

Mn

Al

Ti

Cu

Co

Nb

Fe

Cr

Ni

925

Si

Mn

Al

Ti

Cu

Nb

Mo

Fe

Cr

Ni

926

Si

Mn

N

Cu

Mo

Fe

Cr

Ni

945

Si

Mn

Al

Ti

Cu

Nb

Mo

Fe

Cr

Ni

945X

Si

Mn

Al

Ti

Cu

Nb

Mo

Fe

Cr

Ni

MA956

C

Al

Ti

Fe

Cr

A-286

Si

C

Mn

Al

Ti

V

Mo

Fe

Cr

Ni

020

Si

C

Mn

Cu

Mo

Fe

Cr

Ni

028

Si

Mn

Cu

Mo

Fe

Cr

Ni

DS

Si

C

Mn

Cu

Co

Fe

Cr

Ni

330

Si

C

Mn

Cu

Fe

Cr

Ni

25-6HN

Si

Mn

N

Cu

Mo

Fe

Cr

Ni

27-7MO

Si

Mn

N

Cu

Mo

Fe

Cr

Ni