Inconel Alloy X-750 (UNS N07750)Strip

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Aging Treatment

Customized Hardness

as Required

Excellent High

Temperature Strength

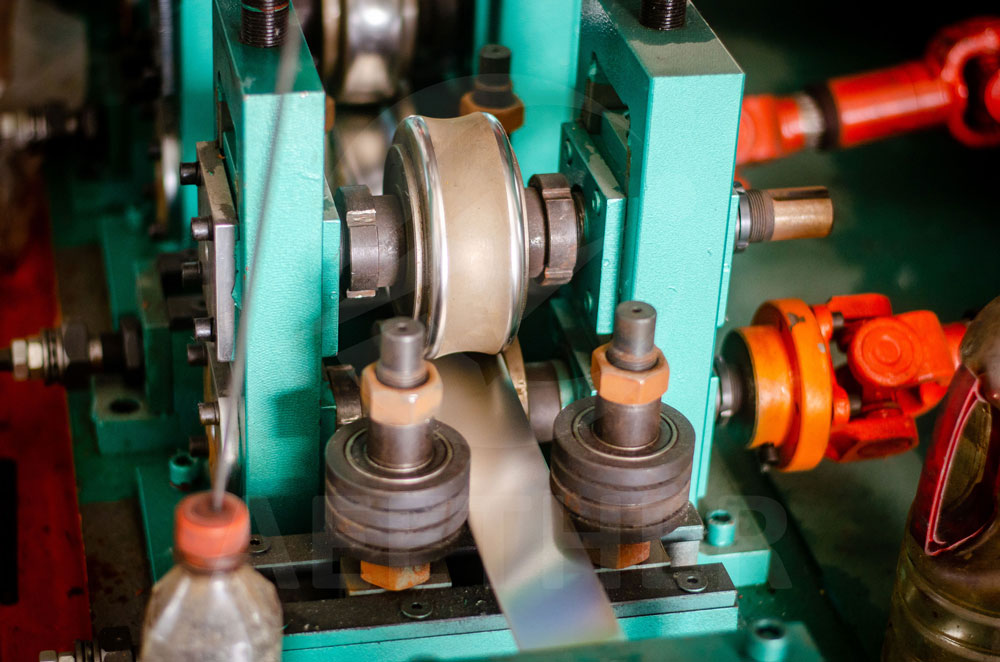

Inconel X-750 Strip Supplier

As a professional nickel alloy supplier, we produce high-quality Inconel X-750 strip. Inconel X-750 strip is a nickel-chromium-based high-temperature alloy with excellent corrosion resistance, high-temperature strength and oxidation resistance. It is widely used in the aerospace, chemical and energy fields.

We provide Inconel X-750 strip in a variety of delivery states, including soft (solid solution), hard (aging) and semi-hard, ensuring that the material can directly adapt to the customer's processing or application requirements. Whether it is a blank that requires further heat treatment or a reinforced material that can be directly formed, we can customize it according to your specific needs. In addition, we support non-standard dimensions and special performance adjustments to ensure that you get the material solution that best meets your project requirements.

With advanced production technology and strict quality control system, we ensure that the chemical composition, mechanical properties and surface quality of each batch of Inconel X-750 strip meet international standards (such as ASTM, AMS, etc.). Whether you need a small batch trial or large-scale procurement, we can provide stable supply and professional after-sales service to help you efficiently advance the project progress.

Chemical Composition of Inconel X-750

*Chemical Composition According to SAE AMS 5598

Customized Dimensions

Tolerance according to ASTM B906

*Customized size please confirm with us

Standards for Inconel X-750 Strip

*As a professional manufacturer, our default standard for Inconel X-750 strip is SAE AMS 5598. We can also produce according to other standards as per you required.

Try our Premium Products

Edge to be Customized

Data Sheet

Physical Properties

| Density | g/cm3 | 8.28 | |

|---|---|---|---|

| lb/in.3 | 0.299 | ||

| Melting Range | °F | 2540 - 2600 | |

| °C | 1393 - 1427 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Solution Treated / Up to 0.25mm, excl | 965 | ... | ... | ... | ... |

| Solution Treated / 0.25 to 4.75mm, incl | 931 | ... | 18 | ... | ... |

| Aging Treated / Up to 0.25mm | 1069 | ... | ... | ... | 30C min |

| Aging Treated / 0.25 to 4.75mm | 1103 | ... | 12 | ... | 30C min |

*Mechanical Properties According to SAE AMS 5598

The alloy can significantly improve its mechanical properties through aging heat treatment, allowing it to maintain excellent stability and durability under high temperature and high pressure environments. After aging treatment, the yield strength and tensile strength of Inconel X-750 strip are greatly improved, while maintaining good ductility and fatigue resistance, which can meet the use requirements under harsh working conditions.

Other Informations

Package

Plastic Bag

Carton Box

Wood Reel

Wooden Pallet

Logistics

By Sea

By Air