Inconel Alloy 718 (UNS N07718 / W.Nr. 2.4668)Plate

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Aging Treatment

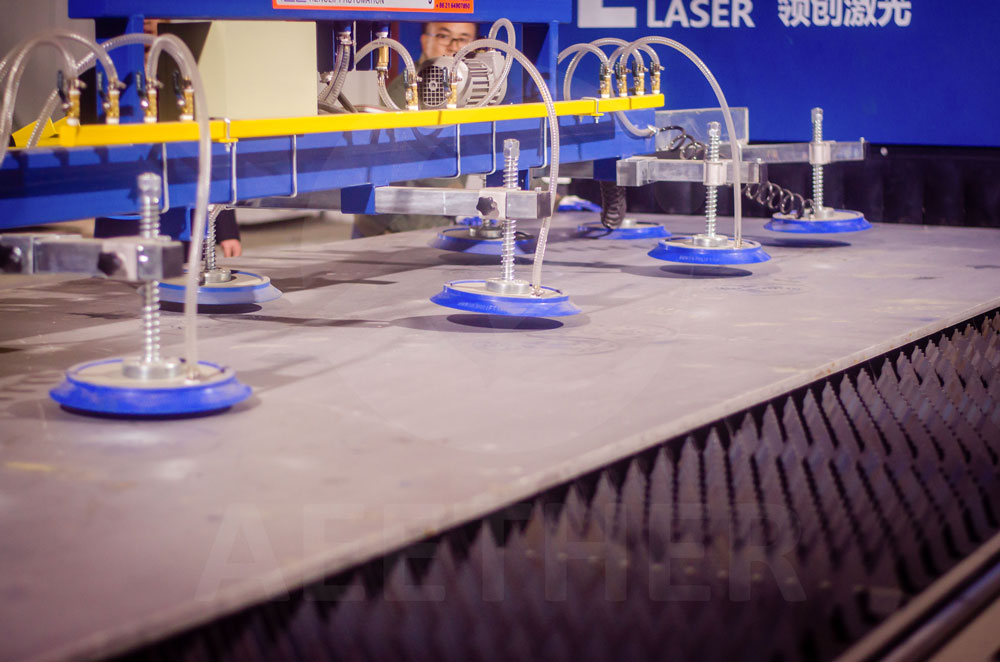

Laser / Water Jet

Cutting Available

Excellent High

Temperature Strength

Inconel 718 Plate Supplier

As a well-known nickel alloy supplier, we produce a variety of Inconel 718 plates.

Inconel 718 plate is a high-performance nickel-chromium high-temperature alloy, known for its excellent strength, corrosion resistance and high temperature resistance. It is widely used in the aerospace, petrochemical and energy fields. The material can still maintain excellent mechanical properties under extreme conditions, especially suitable for long-term use under high temperature and high pressure conditions.

The Inconel 718 plate we provide can be cut in a variety of precision according to customer needs to ensure the dimensional accuracy and surface quality of the finished product. Whether it is laser cutting, water jet cutting or plasma cutting, we can complete it efficiently to meet the requirements of different shapes and sizes. Laser cutting is suitable for high-precision thin plate processing, water jet cutting can achieve complex contour processing without heat-affected zone, and plasma cutting is suitable for efficient forming of thicker plates. We are committed to providing customers with flexible processing solutions to ensure that each plate can perfectly adapt to the final application scenario.

Chemical Composition of Inconel 718

*Chemical Composition According to ASTM B670

Customized Dimensions

Tolerance according to ASTM B906

*Customized size please confirm with us

Standards for Inconel 718 Plate

*We will strictly produce Inconel 718 Plate according to the standard

Try our Premium Products

Surface

Data Sheet

Physical Properties

| Density | g/cm3 | 8.19 | |

|---|---|---|---|

| lb/in.3 | 0.296 | ||

| Melting Range | °F | 2300 - 2437 | |

| °C | 1260 - 1336 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Up to 1.0 (25.4), incl | 1241 | 1034 | 12 | ... | ... |

| Over 1.0 to 2.25 (25.4 to 57.2), incl | 1241 | 1034 | 10 | ... | ... |

*Mechanical Properties According to ASTM B670

Through aging heat treatment, Inconel 718 plate can significantly improve its hardness and tensile strength, so that it can play a better performance in key structural parts. The material after aging treatment not only has a longer fatigue life, but also maintains stability under complex stress conditions, meeting high-standard industrial needs.

Other Informations

Package

Brown Paper

Wooden Pallet

Logistics

By Sea

By Air