Inconel Alloy 690 (UNS N06690 / W.Nr. 2.4642)Strip

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

Customized Hardness

as Required

Excellent High-temp

Oxidation Resistance

Inconel 690 Strip Supplier

In extremely high temperature and corrosive environments, the stability of material properties is crucial. Inconel 690 alloy strip has become an ideal choice for high-end industrial fields such as aerospace, chemical industry, and nuclear energy due to its excellent oxidation resistance, high temperature resistance, and excellent mechanical properties.

Inconel 690 is a nickel-chromium-based superalloy with a chromium content of up to 27-31%, which allows it to form a dense chromium oxide (Cr₂O₃) protective layer in a high temperature environment, effectively resisting oxidation, sulfidation, and carburization. Even at extreme temperatures above 1000°C, it can still maintain excellent oxidation resistance, far exceeding ordinary stainless steel and heat-resistant steel.

In addition, the high nickel content (≥58%) of Inconel 690 alloy strip gives the material excellent high-temperature corrosion resistance, especially suitable for strong acid, strong alkali and molten salt environments. In the nuclear industry, Inconel 690 can withstand high-temperature and high-pressure steam corrosion for a long time and is the preferred material for steam generator pipes.

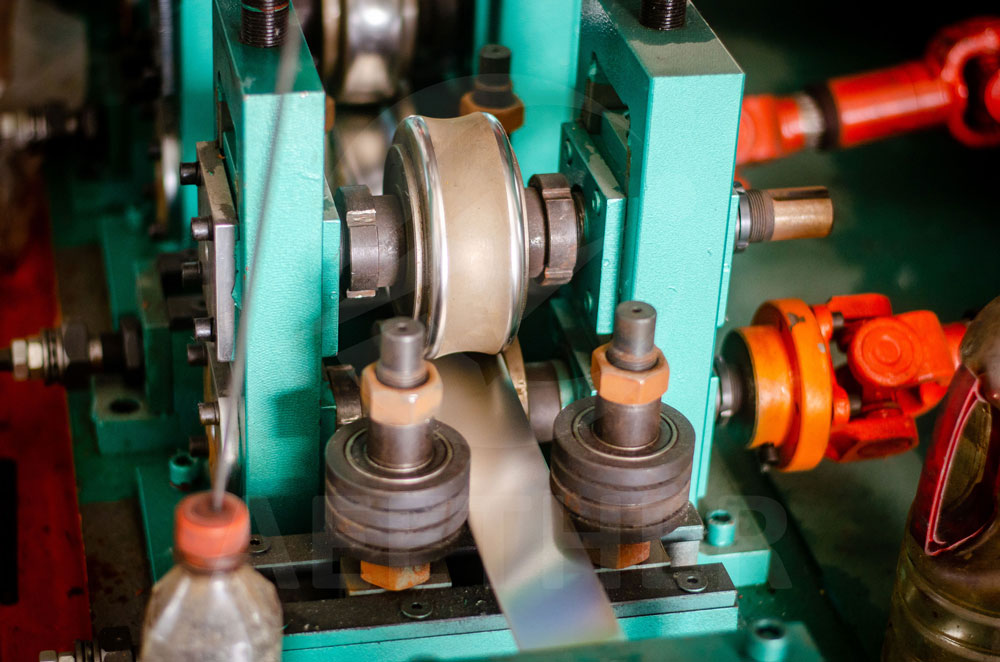

Through advanced cold rolling and heat treatment processes, we can accurately control the tensile strength and hardness of Inconel 690 strip to adapt to different application scenarios.

Chemical Composition of Inconel 690

*Chemical Composition According to ASTM B168

Customized Dimensions

Tolerance according to ASTM B906

*Customized size please confirm with us

Standards for Inconel 690 Strip

*As a professional manufacturer, our default standard for Inconel 690 strip is ASTM B168. We can also produce according to other standards as per you required.

Try our Premium Products

Edge to be Customized

Data Sheet

Physical Properties

| Density | g/cm3 | 8.19 | |

|---|---|---|---|

| lb/in.3 | 0.296 | ||

| Melting Range | °F | 2450 - 2510 | |

| °C | 1343 - 1377 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Annealed | 586 | 240 | 30 | ... | ... |

| Skin-hard | ... | ... | ... | ... | B85 to B88 |

| Quarter-hard | ... | ... | ... | ... | B88 to B94 |

| Half-hard | ... | ... | ... | ... | B93 to B98 |

| Three-quarter-hard | ... | ... | ... | ... | B97 to C25 |

| Hard | 860 | 620 | 2 | ... | ... |

| Spring | ... | ... | ... | ... | C30 min |

*Mechanical Properties According to ASTM B168

Other Informations

Package

Plastic Bag

Carton Box

Wood Reel

Wooden Pallet

Logistics

By Sea

By Air