Inconel Alloy 686 (UNS N06686 / W.Nr. 2.4606)Plate

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

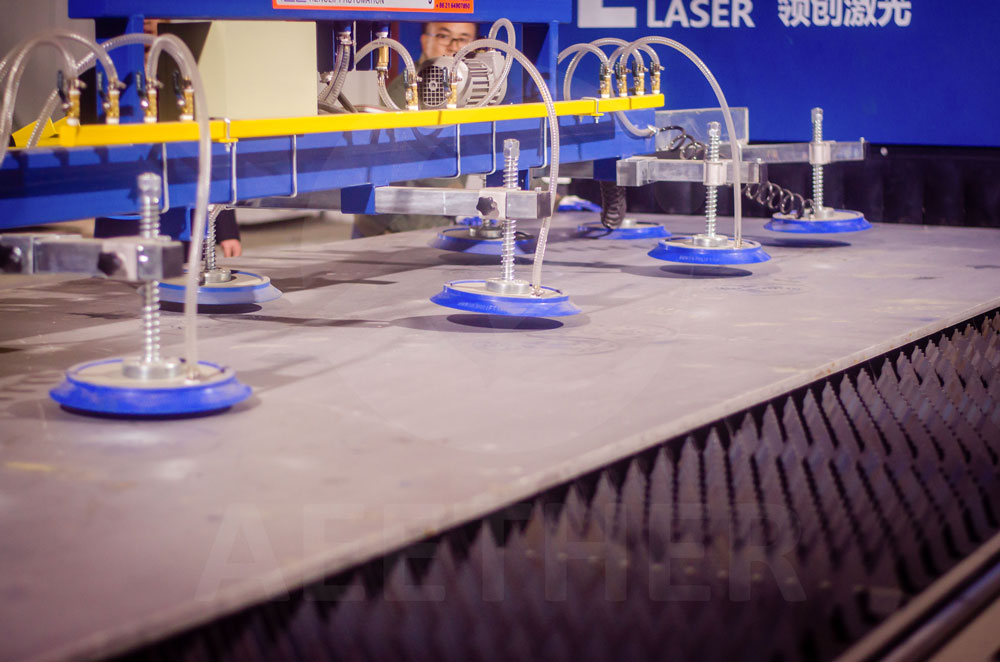

Laser / Water Jet

Cutting Available

Comprehensive

Corrosion Resistance

Inconel 686 Plate Supplier

As a professional superalloy supplier, we supply high-quality Inconel 686 plates.

In addition to excellent corrosion resistance and high temperature performance, Inconel 686 plates also have good processability and weldability, which can meet the manufacturing needs of complex engineering structures. Whether it is a reactor in a strong acid environment, seawater treatment equipment, or high-temperature and high-pressure oil and gas extraction components, Inconel 686 plates can provide long-term and reliable performance guarantee.

In order to meet the processing needs of different customers, we provide a variety of cutting methods to ensure that you get the exact plate size. Whether it is laser cutting, water jet cutting or plasma cutting, we can complete it efficiently, ensuring that the cut is smooth and deformation-free to meet your precision processing requirements. We can also provide customized cutting services according to your specific needs to ensure that each Inconel 686 plate can perfectly fit your application scenario.

Chemical Composition of Inconel 686

*Chemical Composition According to ASTM B575

Inconel 686 is a high-performance nickel-chromium-molybdenum-tungsten alloy designed for extreme corrosive environments with excellent resistance to pitting, crevice corrosion and stress corrosion cracking. Its high content of chromium, molybdenum and tungsten gives it excellent chemical corrosion resistance, especially in acidic, chloride and oxidizing media.

Customized Dimensions

Tolerance according to ASTM B906

*Customized size please confirm with us

Standards for Inconel 686 Plate

*We will strictly produce Inconel 686 Plate according to the standard

Try our Premium Products

Surface

Data Sheet

Physical Properties

| Density | g/cm3 | 8.73 | |

|---|---|---|---|

| lb/in.3 | 0.315 | ||

| Melting Range | °F | 2440 - 2516 | |

| °C | 1338 - 1380 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell B, max | |

| All | 690 | 310 | 45 | ... | 100 |

*Mechanical Properties According to ASTM B575

Inconel 686 can still maintain excellent mechanical strength and stability in high temperature environments, and is suitable for harsh fields such as chemical industry, marine engineering, oil and gas, and pollution control.

Other Informations

Package

Brown Paper

Wooden Pallet

Logistics

By Sea

By Air