Inconel Alloy 601 (UNS N06601 / W.Nr. 2.4851)Seamless Pipe & Tube

- AEETHER

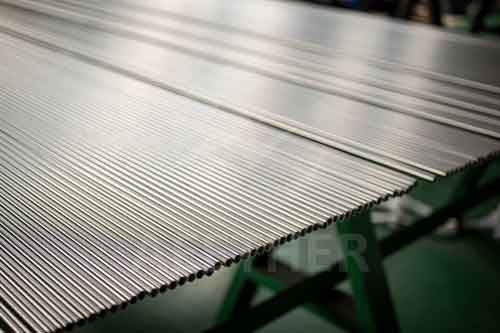

- Inconel Alloy 601 Pipes

- Seamless Pipe & Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

100% Tested by

Hydrostatic Pressure

Excellent

Oxidation Resistance

Inconel 601 Seamless Pipe & Tube Supplier

As a professional nickel alloy supplier, we supply high-performance Inconel 601 seamless pipe & tube.

Inconel 601 is a nickel-chromium alloy with excellent high-temperature oxidation resistance, excellent mechanical properties and good corrosion resistance, suitable for industrial applications in extreme environments. Our Inconel 601 seamless pipe & tube are made of high-quality raw materials through advanced cold rolling or cold drawing processes to ensure that the pipes have uniform microstructure and excellent mechanical strength. The products undergo strict quality control, including dimensional accuracy inspection, surface finish inspection, and non-destructive testing (such as ultrasonic or eddy current testing) to ensure that each pipe meets international standards (such as ASTM B167, ASME SB167, etc.). In addition, we can also provide a full set of test reports such as chemical composition analysis, mechanical property testing (such as tensile, hardness testing) and metallographic inspection according to customer needs to ensure the reliability and durability of the products in high temperature, high pressure or corrosive environments.

Chemical Composition of Inconel 601

*Chemical Composition According to ASTM B167

Inconel 601 seamless pipe & tube can maintain stable performance at high temperatures due to their high content of nickel (about 58-63%) and chromium (about 21-25%), and are particularly suitable for long-term use in oxidizing and carburizing atmospheres.

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Inconel 601 Seamless Pipe & Tube

*We will strictly produce Inconel 601 Seamless Pipe & Tube according to the standard

Try our Premium Products

Surface to be Customized

*We can also sandblast the pipes according to your requirements

Data Sheet

Physical Properties

| Density | g/cm3 | 8.11 | |

|---|---|---|---|

| lb/in.3 | 0.293 | ||

| Melting Range | °F | 2480 - 2571 | |

| °C | 1360 - 1411 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Cold-worked annealed or hot-worked annealed / All sizes | 550 | 205 | 30 | ... | ... |

*Mechanical Properties According to ASTM B167

Inconel 601 seamless pipe & tube are widely used in the manufacture of high-temperature components in heat treatment equipment, chemical processing, aerospace and energy industries due to their excellent creep resistance and thermal fatigue properties.

Inconel 601 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air