Hastelloy Alloy G-35 (UNS N06035)Seamless Pipe & Tube

- AEETHER

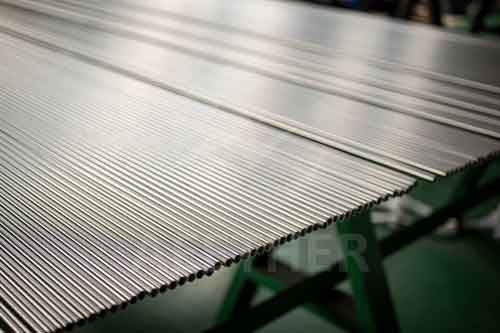

- Hastelloy Alloy G-35 Pipes

- Seamless Pipe & Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

100% Tested by

Hydrostatic Pressure

Excellent

Oxidation Resistance

Hastelloy G-35 Seamless Pipe & Tube Supplier

As a professional nickel alloy supplier, we produce a variety of Hastelloy G-35 seamless pipe & tube.

Hastelloy G-35 seamless pipe & tube is a high-performance nickel-based alloy material. With its unique chemical composition, it exhibits excellent stability and durability in extremely corrosive environments. The chemical composition of Hastelloy G-35 seamless pipe & tube is precisely proportioned, making it an ideal choice for key components in the fields of chemical, petroleum, environmental protection and energy. Its uniform microstructure and seamless design not only improve the pressure bearing capacity, but also avoid the risk of fluid media residue or leakage on the pipe wall. Whether it is a high-concentration chloride environment or a strong oxidizing acid condition, the material can maintain a low corrosion rate for a long time, significantly extending the service life of the equipment.

We focus on providing customers with flexible and customized Hastelloy G-35 seamless pipe & tube solutions. Special sizes can be customized according to actual needs, including non-standard outer diameters, wall thicknesses and lengths to meet the integration requirements of different equipment. From small-diameter precision pipes in laboratories to large-diameter industrial-grade pipes, we strictly control the production process to ensure that the chemical composition, mechanical properties and corrosion resistance of each pipe meet industry standards.

Chemical Composition of Hastelloy G-35

*Chemical Composition According to ASTM B622

Hastelloy G-35 seamless pipe & tube uses nickel as the main matrix, and enhances its anti-oxidation and acid corrosion resistance by adding a high proportion of chromium (about 33%) and molybdenum (about 8%), especially in sulfuric acid, phosphoric acid and mixed acid media. In addition, the addition of copper (about 1.5%) further improves its corrosion resistance to reducing media, while the low carbon content (≤0.015%) effectively reduces the risk of intergranular corrosion, ensuring that the material can maintain st

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Hastelloy G-35 Seamless Pipe & Tube

*We will strictly produce Hastelloy G-35 Seamless Pipe & Tube according to the standard

Try our Premium Products

Surface to be Customized

*We can also sandblast the pipes according to your requirements

Data Sheet

Physical Properties

| Density | g/cm3 | 8.22 | |

|---|---|---|---|

| lb/in.3 | 0.297 | ||

| Melting Range | °F | 2430 - 2482 | |

| °C | 1332 - 1361 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| All | 586 | 241 | 30 | ... | ... |

*Mechanical Properties According to ASTM B622

Hastelloy G-35 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air