Overview

Monel alloy, as an important high-performance alloy, has been widely used in many industrial fields. Its excellent corrosion resistance and excellent mechanical strength make it one of the preferred materials for marine applications. However, what you may not know is that the application of Monel alloy in the manufacturing of electronic components also cannot be ignored.

With the rapid development of electronic technology, the performance requirements of electronic components are also constantly improving. Electronic components must work stably under various environmental conditions. It needs to have properties such as high electrical conductivity, corrosion resistance and processability at the same time. In this article, we will delve into the application of Monel alloys in electronic components and its potential impact on future electronic technology.

In this article, we will first introduce the basic properties of Monel alloy, including its physical and chemical properties and electrical properties. Next, we will explore the specific applications of Monel alloys in electronic components. Finally, we will discuss the future prospects of Monel alloys in the electronics industry, including possible new application areas and potential challenges. By in-depth understanding of the advantages and potential of Monel alloys, we can better understand its importance in the electronics industry and provide strong support for future electronic technology development.

Characteristics of Monel alloy

Monel alloy is a class of high-performance alloys composed of nickel and copper. It has unique physical, chemical and electrical properties that make it popular in electronic component manufacturing.

Physical and Chemical Properties

The main components of Monel alloy are nickel and copper.

Nickel brings excellent austenitic structural stability to the alloy. This allows it to have good plasticity over a relatively wide temperature range and can be processed into very precise shapes and sizes.

Copper brings good oxidation resistance and electrical conductivity to the alloy. Monel alloys are known for their excellent corrosion resistance, especially to salt water, acidic and alkaline environments.

Monel alloys also have good mechanical strength, which is crucial for the structural stability of electronic components.

Electrical Properties

Monel alloy has good electrical conductivity, making it one of the preferred materials in electronic components. Its electrical conductivity, while not as good as pure copper, is sufficient for most applications.

Most Monel alloys are non-magnetic, which is critical to the performance of certain electronic components because it is not affected by external magnetic fields.

Workability and Plasticity

Monel alloy has good processability and plasticity. It can be formed, welded and machined in a variety of ways. This property makes it suitable for complex electronic component design and manufacturing.

Monel alloy maintains stability in high-temperature environments, which is very important for some electronic components that need to operate under certain high-temperature conditions.

In addition, Monel alloys often have excellent welding properties. This allows for better connections in electronic components.

Monel Alloy Applications in Electronic Components

Monel alloys have a variety of important applications in the manufacturing of electronic components. These applications take advantage of its superior properties to improve the performance and reliability of electronic components. Here are some of the main application areas:

Connectors and Sockets

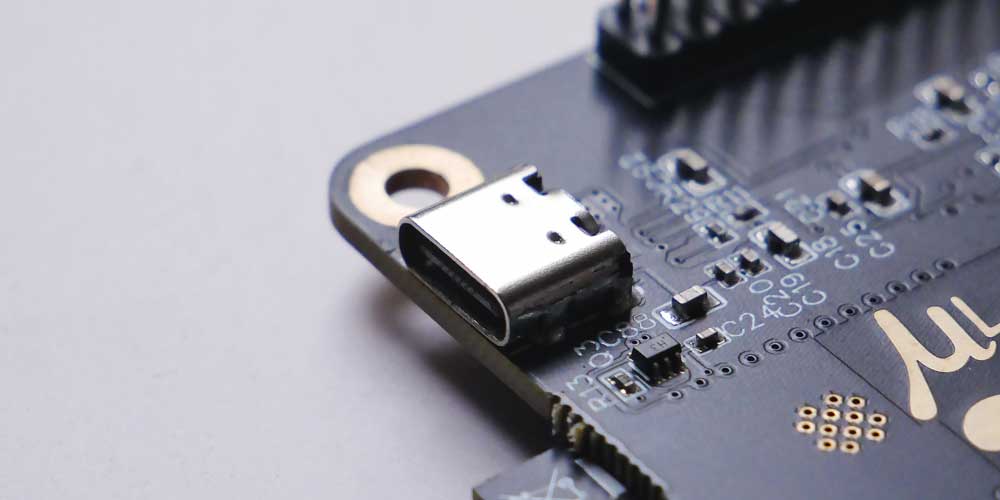

Connectors and sockets are critical components in electronic components, and they must be able to connect reliably under various environmental conditions. The corrosion resistance of Monel alloy makes it ideal for demanding connectors.

Although the electrical conductivity of Monel alloy is not as high as that of copper, it is sufficient to meet the conductive requirements of connectors and sockets. Compared with pure copper, Monel alloy has higher mechanical strength and corrosion resistance, and these properties are more suitable for use under harsh conditions.

Electronic Packaging

In some electronic components, it is necessary to resist the influence of high temperature environment, such as electronic packaging materials. Monel alloy remains stable at high temperatures, so it is widely used in electronic packaging to ensure that packaged components can operate reliably in high-temperature environments.

In addition, electronic packaging must be able to prevent corrosion and damage to internal electronic components from the external environment. Monel alloy's excellent corrosion resistance makes it an ideal material for electronic packaging, especially in environments with corrosive gases or liquids.

Heat Sink

Monel alloy has reasonable thermal conductivity, which makes it an excellent material for thermal heat sinks. Electronic components generate heat during operation, and thermal heat sinks can help effectively disperse the heat to the surrounding environment to ensure stable performance of the components.

Due to the corrosion resistance and high temperature stability of Monel alloy, the heat sink can operate stably for a long time without being affected by environmental factors. This is crucial for some electronic components that need to run for a long time.

The Prospects of Monel Alloys in the Electronics Industry

According to the above introduction, we can know that Monel alloy has been widely used in the electronics industry. In the future, this material is expected to continue to play a key role in promoting the continuous development of electronic technology. Here are some key aspects of the future prospects of Monel alloys in the electronics industry:

Technology Trends and Developments

As electronic products become increasingly miniaturized and multi-functional, the demand for new materials is also increasing. In the future, the high performance and processability of Monel alloy will open up more possibilities for this material.

In addition, as concerns about environmental protection and sustainability increase, the electronics industry will pay more attention to the environmental friendliness of materials. Monel alloy already excels in this regard because it is recyclable and reduces the generation of electronic waste.

Possible New Areas of Application

With the widespread application of 5G technology, the demand for high-performance electronic components will continue to increase. Monel alloy may be used to manufacture antenna connectors and other key components in 5G base station equipment to provide excellent signal transmission performance.

Rapid growth in electric vehicles and renewable energy will also require more high-performance electronic components. These components need to operate reliably under a variety of harsh conditions. The corrosion resistance and high temperature stability of Monel alloys make it a potential choice in these areas.

Potential Challenges and Limitations

The relatively high manufacturing cost of Monel alloys may limit their use in some low-cost electronics. In the future, reducing manufacturing costs may be an important research direction.

Commonly Used Monel Alloys in Electronic Components

Monel 401

Monel 401 is the first Monel material to be used in the electronic components industry. It is the alloy with the highest copper content in the Monel series. Therefore, it has very good electrical conductivity and welding performance.

401

Si

C

Mn

Fe

Cu

Ni

Monel 404

Monel 404 increases the nickel content and appropriately reduces the copper content based on Monel 401. Compared with Monel 401, Monel 404 has better processability and is suitable for processing into more complex electronic components.

404

C

Fe

Cu

Ni

The following is a comparison of the physical properties of these two alloys:

| Monel 401 | Monel 404 | |

|---|---|---|

| Density, g/cm³ | 8.91 | 8.91 |

| Density, lb/in.³ | 0.321 | 0.322 |

| Electrical Resistivity, ohm•circ mil/ft, at 70°F | 294 | 294 |

| Electrical Resistivity, μΩ•m | 0.498 | 0.498 |

Conclusion

The unique properties of Monel alloy, including excellent corrosion resistance, high temperature stability, mechanical strength, welding performance and moderate electrical conductivity, make it one of the ideal materials for electronic component manufacturing. In the fields of electronic connectors, electronic packaging and thermal radiators, Monel alloy has achieved significant applications, improving the performance and reliability of electronic products. In the future of the electronics industry, Monel alloys are expected to continue to play an important role. It may play a key role in new application areas such as 5G technology, electric vehicles, and renewable energy to cope with increasing performance requirements. Although Monel alloys have great potential, they also face some challenges, such as higher manufacturing costs and the need for more research to address new application needs.

We produce high quality Monel 401 and Monel 404 products, please do not hesitate to contact us for any needs.